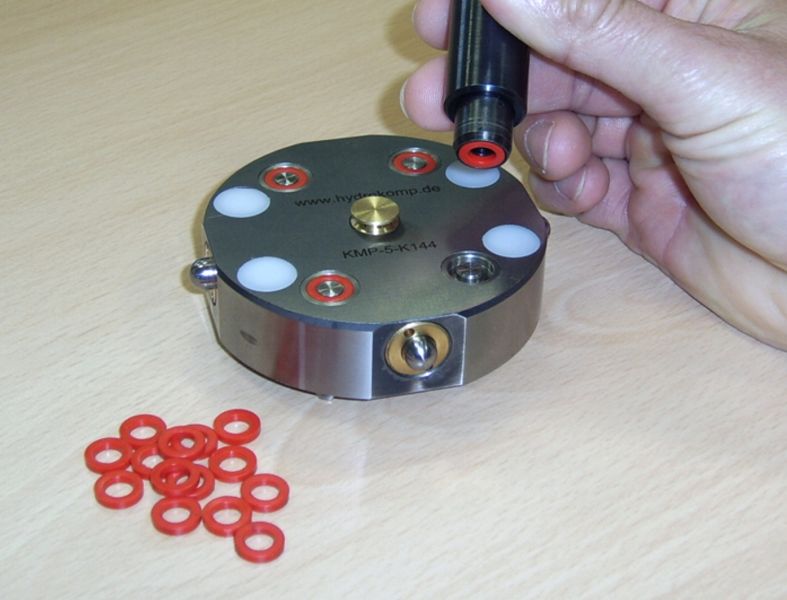

Mounting tools for seal replacement

Description

Coupling mechanisms by HYDROKOMP are designed in such a way that the front system seal can be replaced. This seal is subject to wear in dailly use as a result of contamination and metal fillings. If the coupling mechanism itself shows no damage the system seal can be replaced separately. This can be done by the user or external service personnel. HYDROKOMP has developed a suitable mounting tool to realise the replacement of the system seal simply and safe.

Seal replacement:

Pull out the old damaged system seal from the pilot groove by a scriber.

Insert the new system seal into the peak of the mounting tool manually and set the tool to position above the coupling mechanism.

Through manual pressure insert the system seal exactly and in correct bearing position into the axial groove of the coupling mechanism.

Ist replacement is simple to handle and can be done in only a few minutes to make the coupling mechanism ready for the next use.

-

long service life of the coupling mechanisms

-

minimised machine down time

-

higher availability of machine tools

-

preventive maintenance possible

-

appropriate system seals available

Data sheet 100-5