Multiple coupling systems

Description

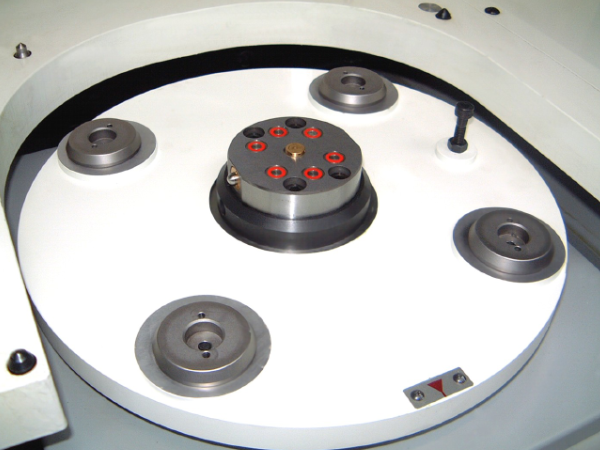

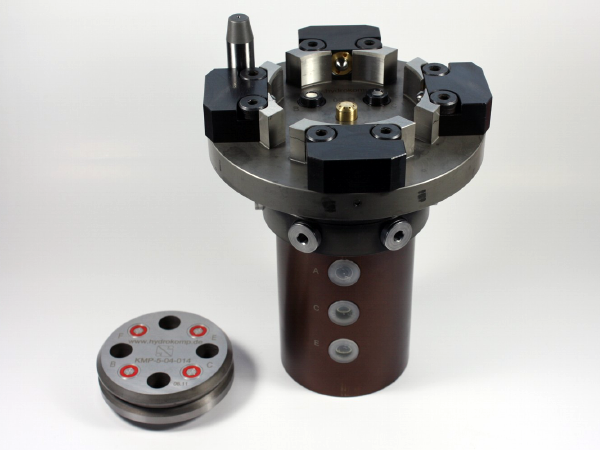

Multiple coupling systems are predominantly used in machine tools, where they serve as the interface for media transmission between the fixture pallet and the loading and unloading station, or the machining station. Applications have been successfully carried out in other areas of engineering, such as handling technology, robotics and in the construction of moulds and dies.

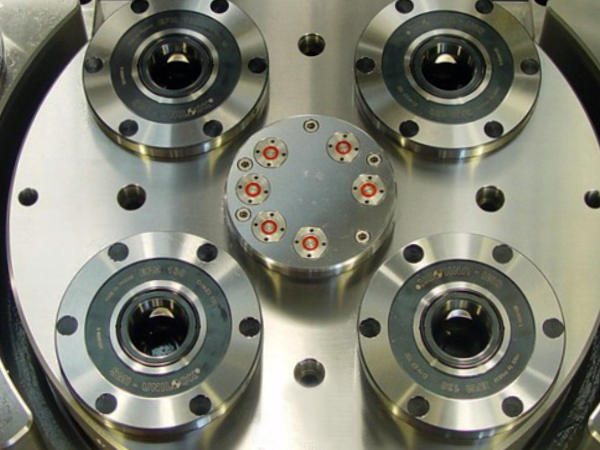

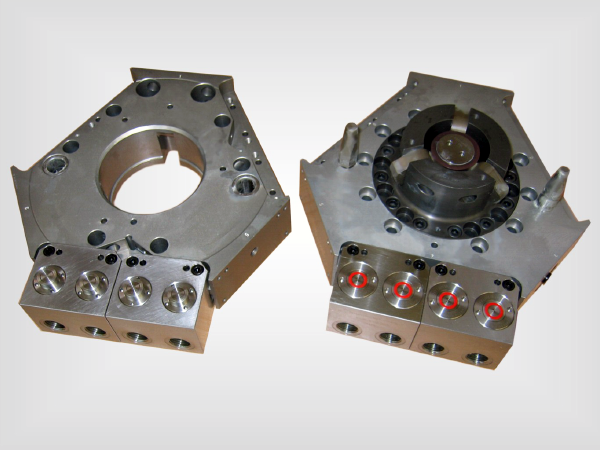

The design of the coupling systems is based on the built-in coupling elements. These are integrated into a common plate in a very compact and functional manner. We provide standardized subassemblies or design and manufacture customer specific coupling systems.

-

different coupling elements can be combined

-

combinable with rotary couplings

-

additional functions can be integrated

-

depressurized or pressurized coupling

-

varied with four nominal diameters

-

transfer of liquid, gaseous media and vacuum

![]()

Functioning:

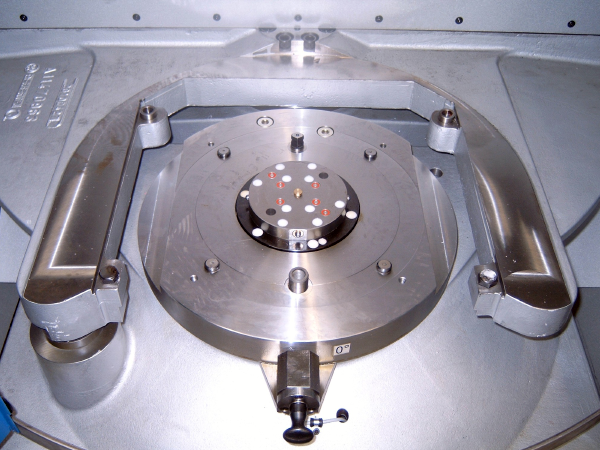

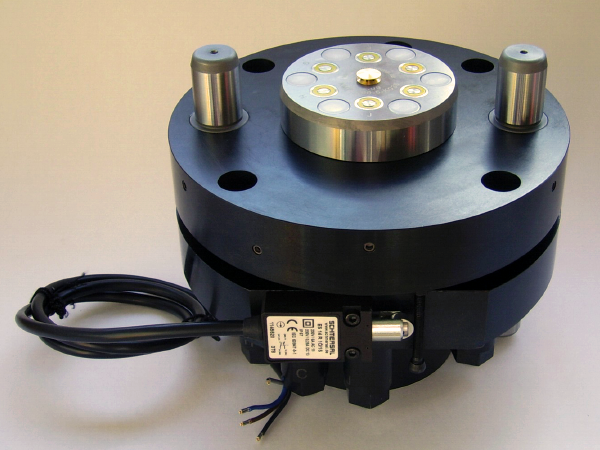

The coupling elements required for the transmission of media are built into common base plates. The coupling mechanism plates are fitted in the operating and machining station, and the coupling nipple plates in the fixture pallets. Depending on the design, various additional functions can be integrated into the coupling plates.

The spring-loaded blast nozzle built into the coupling mechanism plate can be designed in such a way that the jet of air in the coupled state can, for example, be passed on for system monitoring of the workpieces. In order to avoid the clamping of the device pallet and the associated absorption of coupling forces, the coupling systems can be equipped with a self-locking system that saves on additional, expensive clamping elements in the operating station.

The coupling elements themselves are all made of stainless materials. This means that not only hydraulic fluids but also air or vacuum can be transmitted with no difficulty. Coupling elements of different nominal diameters can be combined in a multiple coupling system. Combinations with rotary couplings in the operating station permit the fixture pallet to be turned through 360°, thus providing easy access to the fixture.

Operating conditions:

The coupling elements can be coupled either only when depressurized or when pressurized up to maximum operating pressure, whichever is chosen. If systems are used that can be coupled under pressure, it is, for example, possible to effect a pressure change to the clamping pressure during machining, which is not possible when pilot-controlled check valves are used in the clamping line.![]()

Application examples

![]()

![]()

![]()

![]()

![]()

![]()

Data sheet 100-4