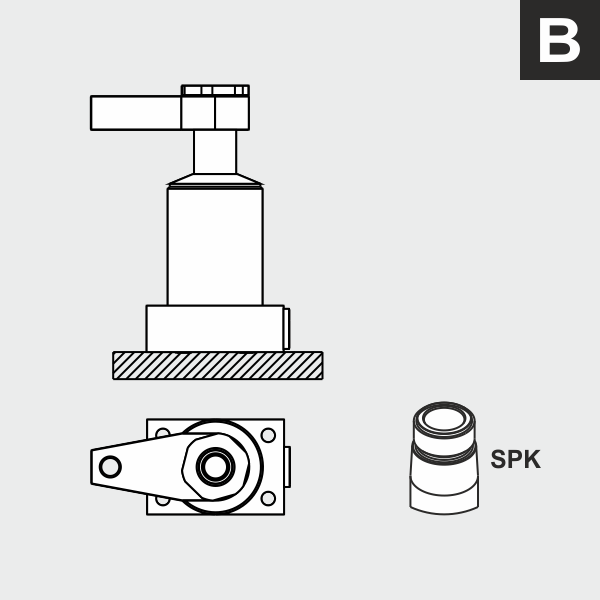

Swing clamps, compact design, with lower flange and threaded body (B)

Description

Swing clamp cylinders operate single-acting with reset spring or double-acting hydraulically. The hydraulic oil supply can be connected by G1/8 threaded port or by manifold connection with O-ring. For any risk of exceeding the permitted volume flow a throttle check valve must be interposed into the oil supply line. Counter-hold the clamping arm when tightening or loosening the fixing cap screw in order to prevent torque transfer to the piston rod and to avoid damage to the ball guide.

The clamping procedure is initiated with a superimposed swing and stroke movement. After that, a linear clamping stroke follows. Cylinders with swing angles 0°, 45°, 60°, 90° are available as standard. The clamping force is depending from the length of the clamping arm. Except for the standard clamping arm also special clamping arms can be assembled. The maximum operating pressure of 350 bar only applies to clamping arms with a maximum length of 26 mm.

-

compact design

-

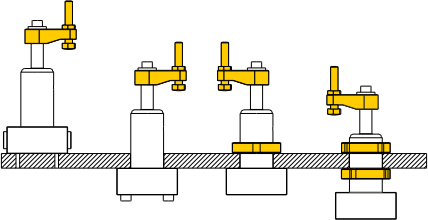

various mounting options

-

standard clamping arms with contact bolts are available as accessories

-

can be equipped with customer specific clamping arms

Designs:

Mounting options:

Data sheet 240-2

Operating pressure:

pmin. 25 bar - pmax. 350 bar

Operating method:

single-acting or double-acting

Swing angle:

0°, 45°, 60° and 90°

Design:

B (lower flange)

Piston Ø:

14 mm

Clamping stroke:

single-acting 6 mm, double-acting 8 mm

Clamping arm holder:

taper with cap screw, ratio 1:10

![]()

Overlod protection:

without

Position control:

without

Oil supply:

threaded port G1/8 or manifold connection with O-ring

Data sheet (download here) and step files on TraceParts:

Selection guide: