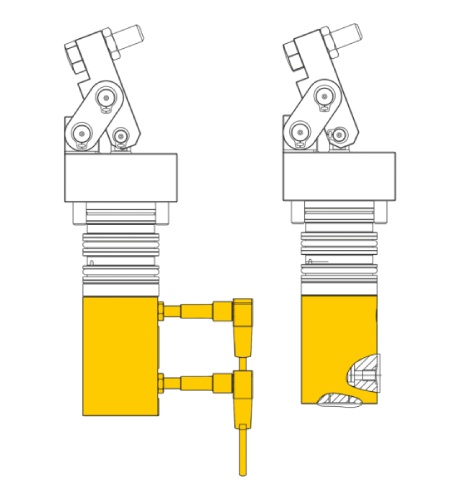

Lever clamps without/with position control

Description

Lever clamp cylinders (lever clamps) are primary meant for individual cases, where the clamping position needs to be free for handling when the workpiece is unclamped. Compared to swing clamps, lever clamps have a more compact design and higher clamping load. Lever clamps are especially meant for those cases, where bothering contours make the use of swing clamps unsuitable. Through a piston the high force density is induced into the clamp lever. Since the clamp lever has a movable position, the clamping point can be fully released. Besides the standard clamp lever also special clamp levers can be mounted. The resulting clamping load can be determined through the chart on the data sheet.

-

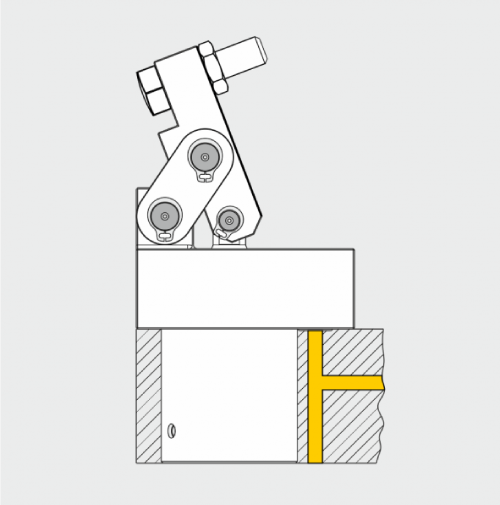

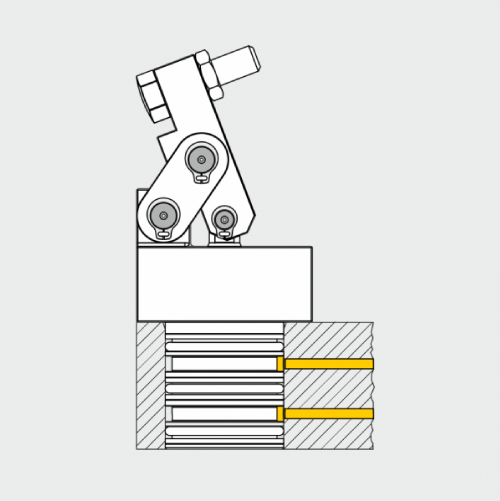

partly retractable housing

-

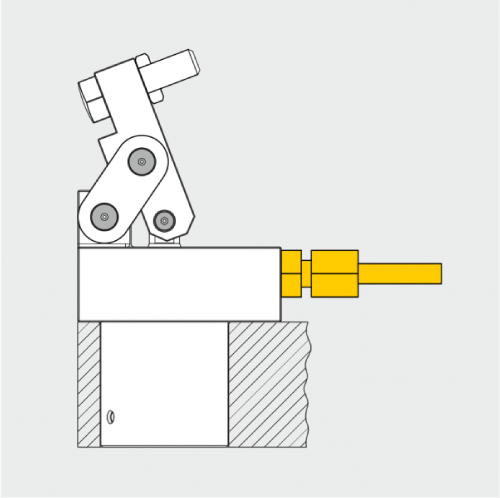

various installation options

-

fixture can be easily loaded and unloaded

-

clamp lever can be optimized on workpiece

-

inductive or pneumatic position control available

-

standard cylinders and special designs available

![]()

Operating conditions:

The lever clamp cylinder is only double-acting, hydraulic. Therefore, clear clamping times and unclamping times are given. For hydraulic oil supply G1/8 resp. G1/4 threaded port or manifold connection with O-ring can be used optional. In horizontal position the clamp lever provides its optimal clamping load. Workpiece tolerances with a position deviation of appr. +/-8.5° can be compensated easily.

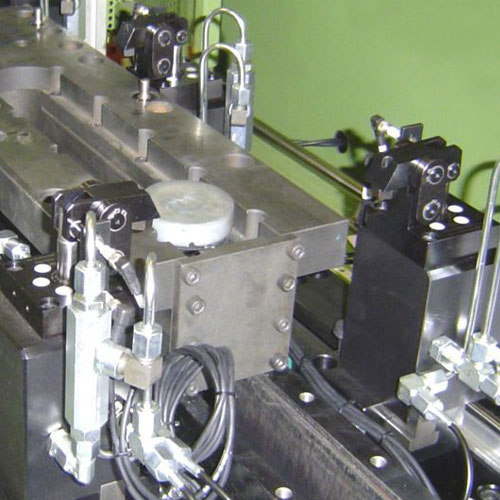

Application example

Brake test bench

Various workpieces are clamped by various adapters. Test specimens are changed every five minutes. Six lever clamp cylinders operate with two clamping circuits. Additional protection is provided by piloted check valves. Originally, the workpieces were fastened with screws.

It used to take one minute to change a workpiece. With the lever clamp cylinders from HYDROKOMP it takes only five seconds to change one workpiece.

Data sheet 250-1

Operating pressure:

pmax. 350 bar (200 bar at piston Ø 40 mm)

Operating method:

double-acting

Piston Ø:

16, 25 and 40 mm

Clamping stroke:

from 1,5 kN at 100 bar up to 19 kN at pmax.

Oil supply:

threaded port G1/8 resp. G1/4 or manifold with O-ring or drilled channels

Sealing:

FKM from -10°C up to 150°C

Wiper:

soft wiper and metal wiper

Data sheet (download here) and step files on TraceParts:

Designs: