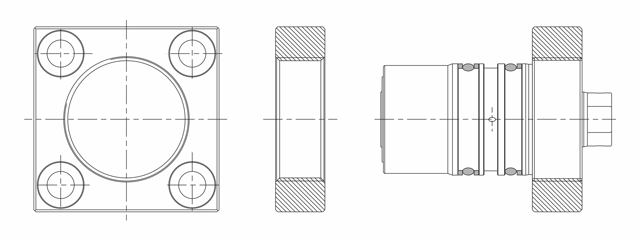

Threaded body cylinders, double-acting

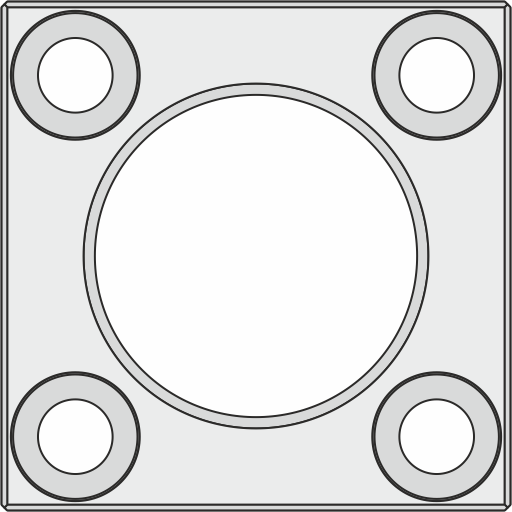

Flange plates (Accessories)

to fix the cylinder with four screws

Contact bolts

for screwing into the

internal thread of

the piston rod

(Accessories)

Description

This cylinder with double acting function saves space when built into fixture plates or into plates of plastic injection moulds. The double acting function makes cycledependant strokes possible when retracting and extending the piston. The operation times can be calculated from the possible flow rate of the power unit and the operated piston or ring area volume.

Unlike with single acting cylinders both stroke directions are power operated. On the piston rod end the cylinders are equipped with a retractable wiper made of NBR/FKM and an additional metal wiper. The metal wiper prevents the penetration of chips into the soft wiper and in this way the piston is prevented from jamming. This preventive measure protects the seals and increases the life of the cylinder.

-

no ingress of chips due integrated metal wiper

-

space-saving positioning possible

-

fully retractable housing

-

oil supply without pipe

-

varied for manifold application options

-

standard cylinders and special designs available on request

![]()

Operating conditions:

Oil is fed to the inside of the fixture body by means of drilled oilways. Meticulous cleanliness is extremely important since drilling chips may damage the seals and cause leakage and the failure of the installation. The cylinder is sealed by means of an O-ring / support ring combination. Due to the compact design the threaded body cylinder does not have an internal stop for the return stroke, but uses the bore bottom of the assembly bore. For that reason the dimension for the installation depth must be adhered to absolutely. The diagonal feeds and cross-bores for the oil supply must be well rounded in order to prevent the seals from being damaged during installation.

![]()

Flange plates:

The flange plates (Accessories) make it is easy to mount the cylinders with four screws.

The thread inside the mounting housing is not necessary.

Application example

Threaded body cylinders in a hydraulic multiple rotary clamping fixture

A rotary valve coupling is installed in the counter-bearing of this clamping fixture so that only the upper facing fixture side can be clamped or released. The function of this rotating connection is based on the principle of a rotary disc.

Hydraulic threaded body cylinders are designed as single-acting tension pull cylinders and are integrated into the fixture body. The pressure oil supply is done within the fixture and only via the drilled oil channels.

With this design, it is possible to supply the fixture with continuous pressure and only the sixth, upwards facing side can be clamped or released. The hydraulic rotary clamping fixture offers enormous economical advantages during processing of rotating workpieces in series manufacture. These are:

-

Multi-side workpiece processing

-

Reduction in tool change times

-

Reduction of workpiece change times

-

High clamping security and quality

-

Increase in machine runtime

Data sheet 200-2

Operating pressure:

pmax. 500 bar

Operating method:

double-acting

Piston Ø:

16, 20, 25, 32, 40 and 50 mm

Stroke:

16, 20, 25, 32, 50, 100 and 160 mm

Thrust force:

from 2 kN at 100 bar up to 98,5 kN at 500 bar

Traction force:

from 1,22 kN at 100 bar up to 57,9 kN at 500 bar

Oil supply:

drilled channels

Sealing:

NBR -10°C up to +80°C, FKM up to 150°C

Wiper:

soft wiper and metal wiper