Sequence valves

Description

The sequence valves are used in the clamping hydraulics as a directly controlled sequence valve. The compact design allows space-saving installation directly in the fixture. The sequence valve is a poppet valve which operates without leakage oil compared to a spool valve. The inlet and outlet pressures of the sequence valves are always identical. As a result this type of valve is ideal for use in sequence control systems. With single-acting cylinders, only one supply line from the pressure supplier (see data sheet 430-1) is required for operation. The design allows valve combinations that can be flanged together to form a block using a common P-connection and standard parts.

-

space-saving installation options

-

quick installation due to flange

-

ideal for pressure sequence control

-

operation with one supply line possible

-

valve combinations possible

-

Integrated check valve

![]()

Valve combinations:

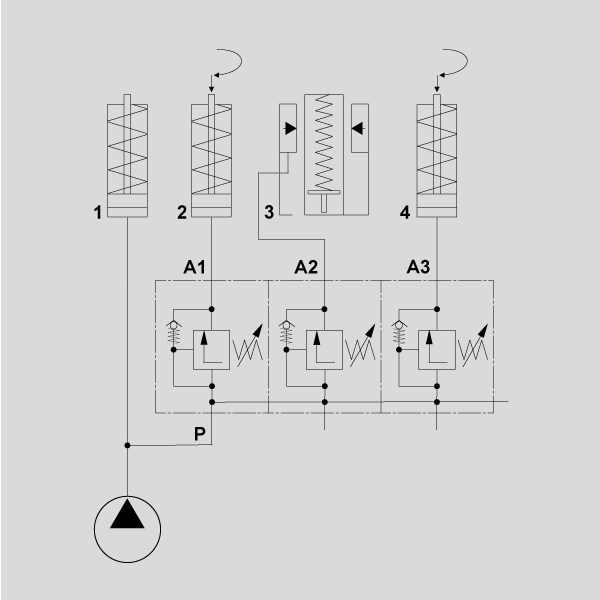

Combinations of sequence valves are assembled from an inlet valve (P) and a maximum of four flange-mounted series valves. These are supplied with pressure oil through holes. Sealing between the valve housings is provided by O-rings. In order to ensure proper functioning with sequence controls, there should be a certain minimum pressure difference from valve to valve..

The drawing shows symbolically a clamping device as it can be used e.g. in manufacturing. When pressure is applied, the single-acting cylinder [1] clampes.

When the set opening pressure has been reached, the inlet valve [A1] opens and actuates the swing clamp [2].

The support element [3] clamps the support piston as soon as the opening pressure in the series valve [A2] is reached.

The series valve [A3] actuates the swing clamp [4] to complete the clamping process.

When the device is released, the pressure oil flows back to the pressure generator via the integrated check valves.

Data sheet 700-2

Designs:

threaded type, threaded port, manifold connection with O-ring and valve combinations

Operating pressure:

pmax. 500 bar

Volume flow:

max. 12 l/min

Adjusting range:

15-80 bar, 30-160 bar, 60-315 bar, 100-500 bar

Pressure change

per revolution:

9 (15-80 bar), 15 (30-160 bar), 32 (60-315 bar), 49 (100-500 bar)

Combinable:

inlet valve + max. 4 sequence valves

Oil supply:

threaded port G1/4 or manifold connection with O-ring

Pressure medium:

hydraulic oil according to DIN 51524 Tl.1 up to 3; ISO VG 10 up to 68 nach DIN 51519

![]()

Data sheet (download here) and step files on TraceParts:

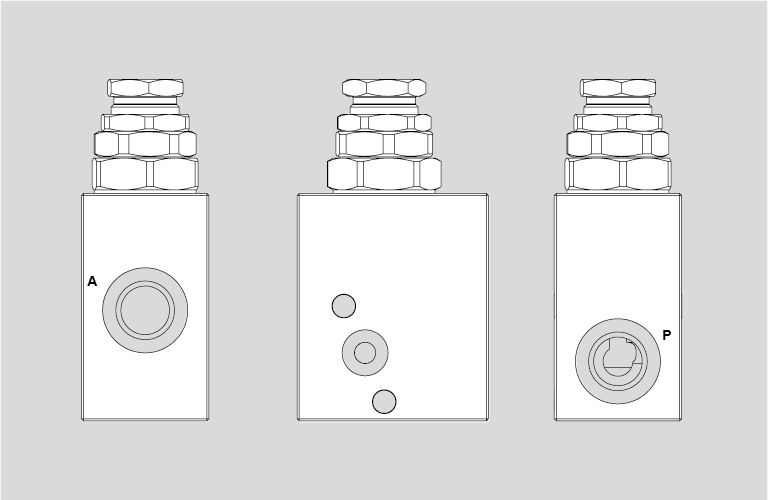

Directly controlled sequence valve designs:

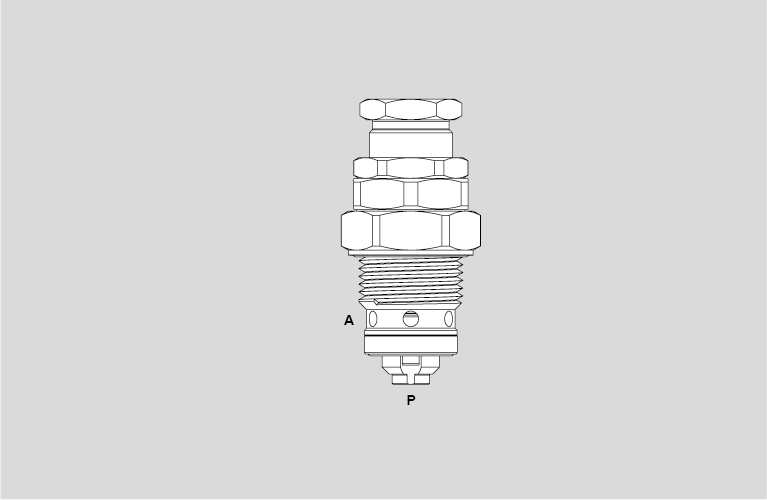

Threaded type

G1/4 threaded port

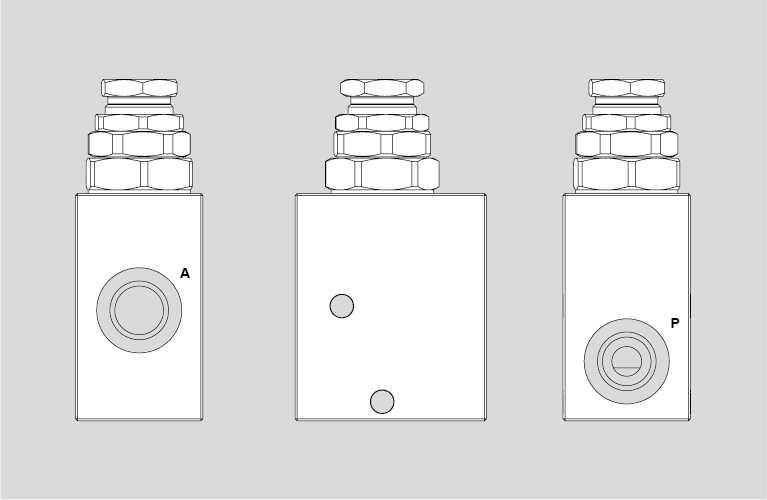

Manifold connection with O-ring

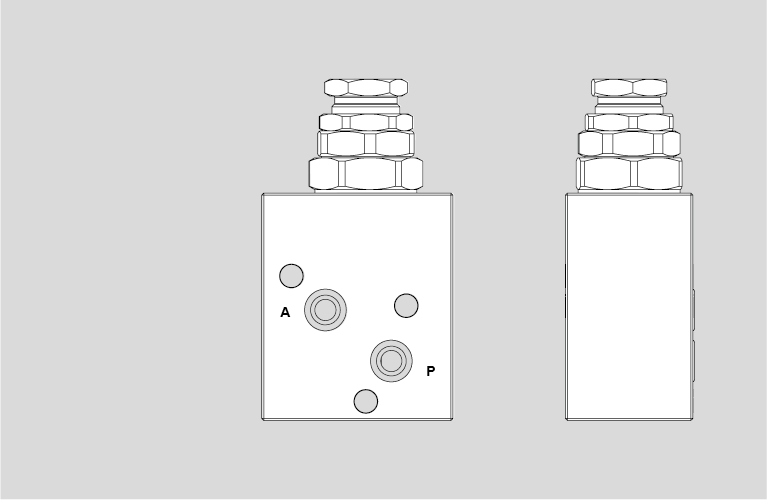

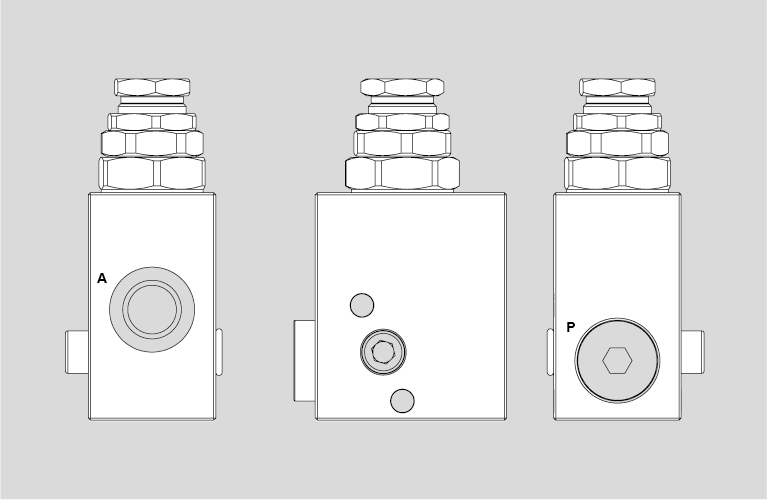

Valve combinations:

Inlet valve with threaded connection

Series valves with threaded connection