Pressure reducing valves

Description

Pressure reducing valves are ideal for the application in static leak-oil free clamping systems, which are decoupled by a pressure pump unit. The function of the pressure reducing valve is to maintain the outlet pressure A on the consumer also with variable, always higher supply pressure P constant.

Once the supply pressure equals the adjusted outlet pressure, a check valve completely blocks the oil flow. Therefore, the pressure can not increase any more. Until the adjusted outlet pressure is acquired, the hydraulic oil can easily flow from P→A through the valve. A pressure spring opens the oil flow against the supply pressure, as soon as the outlet pressure, eg. due to the consumer, decreases. This makes the hydraulic oil flow until the initial pressure is acquired again.

Since this pressure reducing valve does not have a leak-oil port, an supply pressure rise might not be compensated. Reasons for such an unwanted pressure rise can be for example: warming, external influences, effects by foreign matter (chips) in the valve seat etc. Overload balance is not possible due to this pressure reducing valve version.

HYDROKOMP recommends installing a pressure reducing valve between the valve and the consumer. The opening pressure adjusted for the pressure reducing valve may not exceed the max. permissible operating pressure of the consumer. If possible, it should be approx. 10% above the outlet pressure. The outlet pressure can be adjusted by a pressure gauge which also allows the visual control of the outlet pressure.

-

optimal use of clamping force with cylinders and cylinder groups

-

automatic adjustment for outlet pressure

-

ideal for static clamp systems

-

no leak-oil tubes

-

housing with pressure gauge port

-

varied settings possible

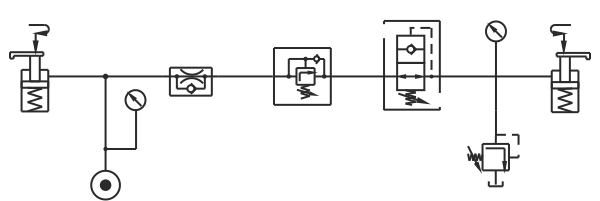

If throttle check valves and sequence valves are to be combined in sequence with the pressure reducing valve, the order described in the example must be considered.

Data sheet 700-30

Design:

2-way poppet valve

Inst. position:

various

Oil supply:

G1/4

Op. pressure:

pmax. 500 bar

Supply pressure:

up to 380 bar

Volume flow:

10 l/min

Temperature:

ambient -40°C...+80°C

Medium:

hydraulic oil acc. to DIN 51524 Tl.1 up to 3; ISO VG 10 up to 68 acc. to DIN 51519

![]()

Data sheet (download here) and step files on TraceParts:

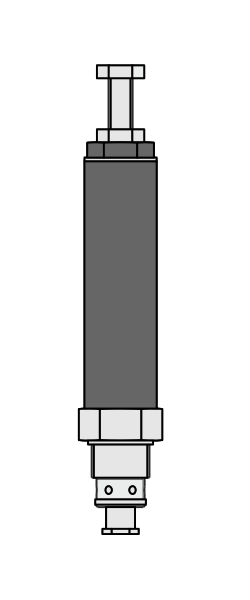

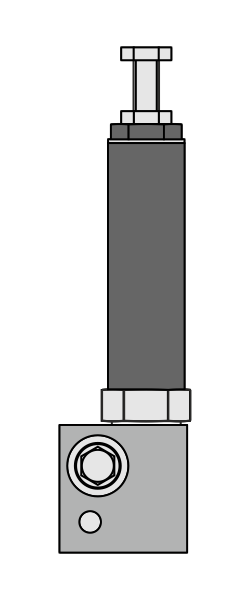

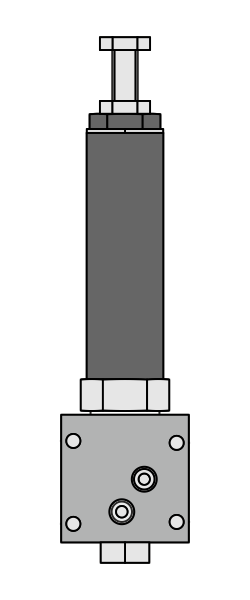

Designs:

![]()