Pressure pump-units, air-hydraulic

Description

These pneumatic hydraulic pressure pumps are suitable for application in simple clamping systems for actuating single-acting or double-acting clamping elements. The pressure pumps convert a pneumatic inlet pressure into a hydraulic operating pressure. Pressure adjustment and compressed air treatment are done in an external maintenance unit.

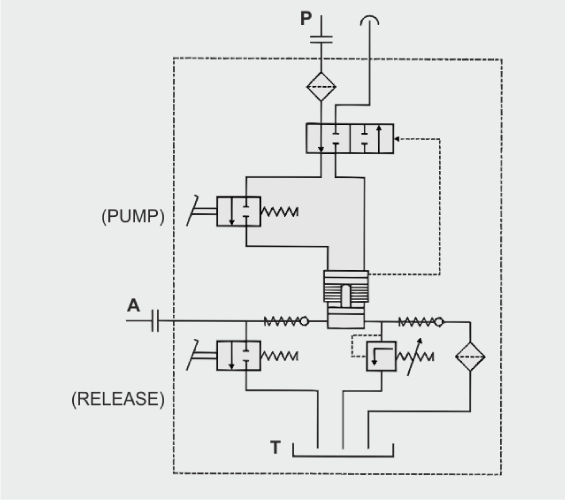

The single-acting pressure pump clamps or unclamps the connected clamping elements by manual operation of the pedal. The pressure pump supplies hydraulic oil until the desired operating pressure is reached. The integrated check valve keeps the oil pressure constantly. In cases of pressure loss e.g. through leakage, automatic replenishment is not given.

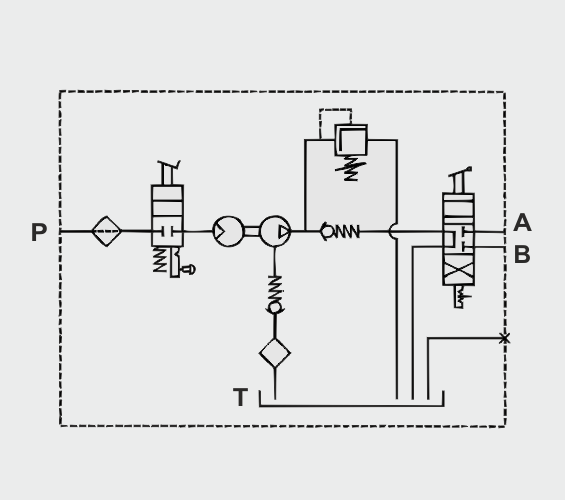

The pressure pump for double-acting clamping elements allows constant pressurization. Clamping and unclamping of the clamping elements is done by using the control lever of the 4/3 directional valve. depending on the position of the directional valve, the clamping elements will extend or retract by pressing the pedal on "PUMP". The pedal must be pressed until the clamping elements have reached their end position and the desired oil pressure is built up. The pedal can be fixed in position by the pedal lock. After that, clamping and unclamping of the clamping elements can de done by using the control lever of the 4/3 directional valve. When the pedal is fixed, the double-acting pressure pump can compensate a low pressure loss automatically.

-

integrated pressure control valve up to 500 bar

-

low weight, easy to transport

-

suitable for mobile use

-

suitable for application in explosive hazardous areas

Important notice:

The pressure pump-units are already filled with oil. They are supplied ready for connection. It is not necessary to use a mist oiler. Scope of supply includes an user’s manual. The safety and maintenance instructions must be observed.

Data sheet 430-1

Operating pressure:

pmin. 50 bar, pmax. 500 bar

Operating method:

single-acting

Inlet pressure:

2,8 - 10 bar (pneumatically)

Flow rate:

max. 1,4 l/min (bei 7 bar)

Oil supply:

G1/4 threaded port (air), G1/4 threaded port (oil)

Air consuption:

400 Nl/min

Oil volume:

2,3 l (usable 2,1 l)

Noise level:

75 dB(A)/1m

Data sheet (PDF):

Designs:

1. Pressure inlet port

2. Pedal "PUMP" (pressure rise)

3. Filling and ventilation plug, at double-acting pressure pump: port for drain into reservoir

4. Pedal "RELEASE" (pressure relief)

5. Ports for hydraulic hoses single-acting: 1 port double-acting: 2 ports

6. Pump body with reservoir

7. Pedal lock (hidden in picture)

8. 4/3 directional valve with control lever

9. Bleed screw

10. Oil level gauge (hidden in picture)

Circuit examples:

single-acting

(PUMP) = clamp / (RELEASE) = unclamp

A. hydraulic port

B. hydraulic port

P. pneumatic port

T. oil reservoir