Coupling elements

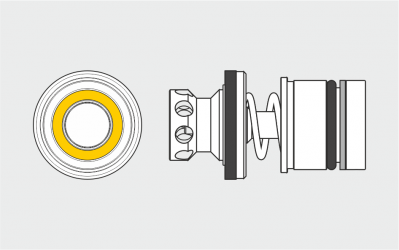

Coupling mechanisms

built-in and threaded body designs

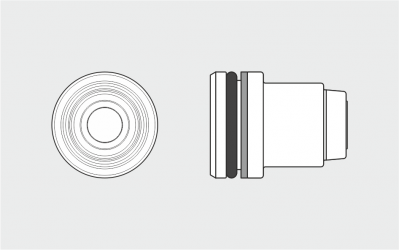

Coupling nipples

built-in and threaded body designs

Screw-in tools

for coupling elements

(Accessory)

Mounting tools

for the replacement

of the system seal at

coupling mechanisms

(Accessory)

Description

Coupling elements of HYDROKOMP are made of stainless materials. This enables the elements to be used for all fluids and gases that are not aggressive. Special designs eg. for water steam or other media are available on request. HYDROKOMP offers coupling elements for two different operating modes depressurized coupling or pressurized coupling. The elements for depressurized coupling can be coupled pressurized up to 25 bar, if the specified volume flow is not be exceeded. When using higher operating pressure there ockures a risk of demaging the soft seal in the check valve as the result of high flow velocities of the fluid. This means for coupling of air up to 10 bar there should be always used the coupling elements for depressurized coupling. This also applies when the coupling process is initiated pressurized. The elements which can be coupled pressurized may be coupled up to the maximum specified operating pressure on one side and / or on both sides.

The built-in elements are particularly suitable for installation in plates of multiple coupling systems. Threaded body elements can be directly scewed into the fixture body, for example of a tool change system. There, they are ideal suitable as an interface for medium transfer.

-

stainless materials and replaceable system seals for long service life

-

ideal for space-saving installation in individual receiving housings

-

transmission of liquid and gaseous mediums and vacuum

-

pressurized or depressurized coupling

-

various with four nominal diameters

-

standard elements and special designs available

-

HT-Variant operating temperature up to 200°C NEU!

![]()

Operating conditions:

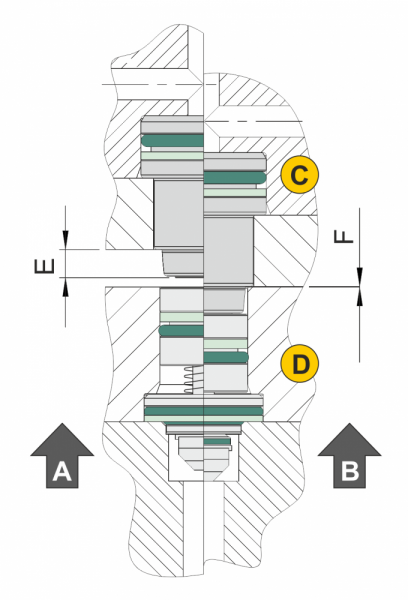

Coupling nipple and coupling mechanism must face coaxially each other before the coupling process. The base plates of both elements must be guided about 2 to 3 mm before contact of the sealing surfaces within the radial positioning tolerance. The coupling force between coupling nipple and coupling mechanism resulting from hydraulic pressure according to the formula has to be compensated positively from the outside.

The axially acting front seal areas must be protected from contamination. Good results can be archieved by rinsing and following blowing-off with compressed air. The sealing of the mechanism is done in the drill base of the mounting hole. The required surface quality in the drawing has to be kept.

B = status coupled

C = coupling nipple

D = coupling mechanism

E = coupling stroke

F = axial position tolerance

Application examples

Single coupling system

with cleaning nozzle, (ND 5) depressurized coupling, housing

according to customer's requirements

Coupling nipple plate

with coupling nipple

threaded-body design

Coupling mechanism plate

with cleaning nozzle,

coupling mechanism

built-in design

Single coupling system

(ND 3) depressurized coupling, housing according to customer's requirements

Coupling mechanism plate

with coupling mechanism

threaded-body design

Coupling nipple plate

with coupling nipple

threaded-body design

Multiple coupling system

The built-in coupling elements are particularly suitable for installation in plates for multiple clamping systems

In these systems different coupling elements can be combined. Also rotary couplings can be integrated as well as

additional functions eg. hydro mechanical locking and cleaning nozzle etc.

Data sheet 100-3

Nominal diameter:

3, 5, 8 and 12

Operating pressure:

pmax. 250 - 500 bar

Flowrate:

8, 12, 25 and 50 l/minute

Coupling stroke:

4,5 , 7, 10 mm

Coupling force:

min. 94, 98, 169 N (at 0 bar)

Design:

built-in and threaded body elements

Operating method:

for pressurized or depressurized coupling

Medium:

fluid or gaseous media or vaccum

Data sheet (PDF):

Designs:

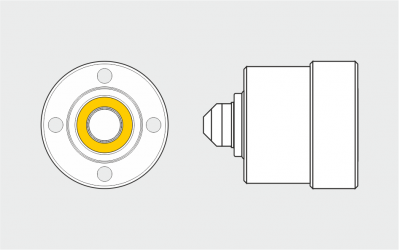

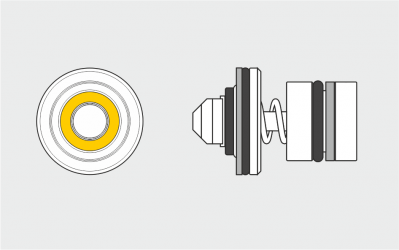

Coupling mechanism threaded body design

Operating method:

- pressurized coupling

(system seal yellow)

- depressurized coupling

(system seal red)

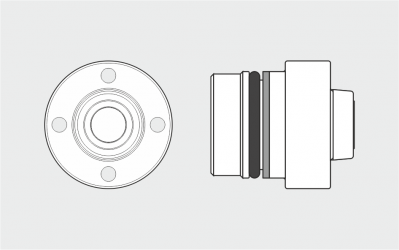

Coupling nipple threaded body design

Operating method:

- pressurized coupling

- depressurized coupling