Locking cylinders without reset spring

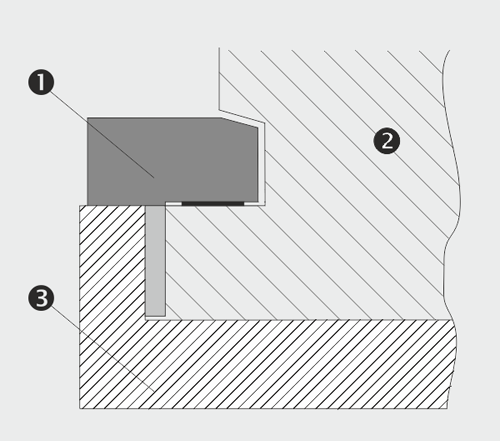

Description

The single-acting locking cylinder is suitable for locking of movable machine tables. It is equipped with either one or two pistons. The loading of the piston is done hydraulically via a centralized pressure system connected to a G1/4 threaded port. Each piston has its separate port. Various locking cylinders can be integrated into the machine control system. The relief of the piston is effected by the pressure reduction in the pressure system.

Important instructions:

The locking cylinder does not have any safety device to prevent the piston from falling out of the housing. It is not allowed to pressurise the locking cylinder if there is no counter surface for the piston.

To increase the operational safety during the application of locking cylinders, we recommend the installation of pressure monitoring elements in each hydraulic circuit. If possible, the locking cylinder should be connected via two seperate hydraulic circuits. Each should be secured by a check valve.

-

compact design

-

high locking forces

-

locking pressure can be monitored

-

full use of pressure

-

relief effected by pressure reduction

-

standard cylinders and special designs available

Application example:

Data sheet 230-2

Operating pressure:

pmax. 500 bar

Operating method:

single-acting without reset spring

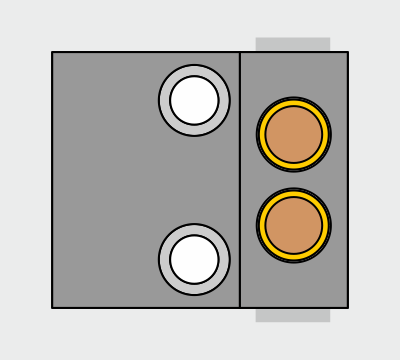

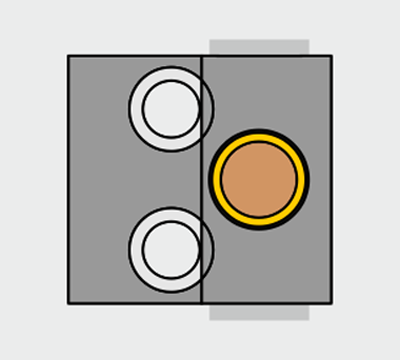

Piston:

with 1 or 2 pistons available

Stroke:

5 mm (1 piston), 2 mm (2 pistons)

Clamping force:

from 4,9 kN at 100 bar up to 49 kN at 500 bar![]()

Oil supply:

threaded port G1/4

Sealing:

NBR -10°C up to +80°C

Data sheet (download here) and step files on TraceParts:

Designs:

with 1 piston

available in two lengths

locking force up to 24,5 kN