Rotary lever clamps, hydraulically and pneumatically

Description

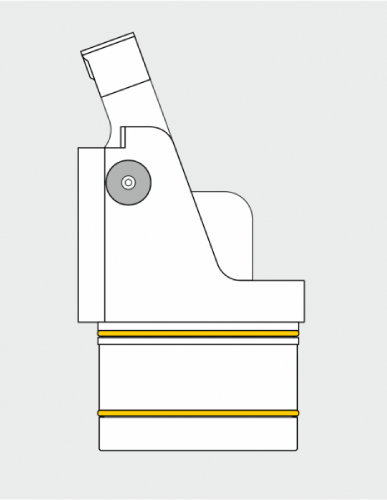

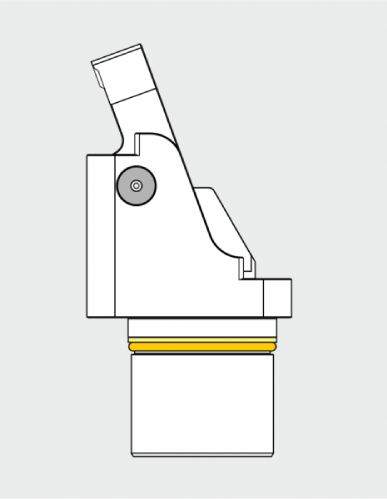

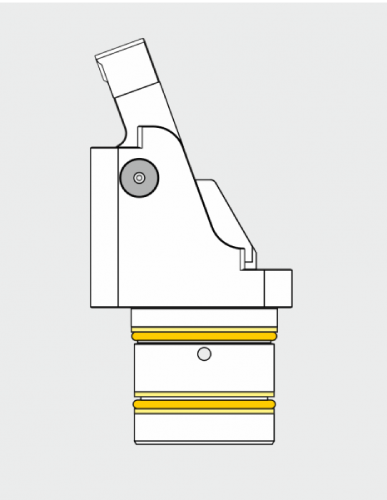

The rotary lever clamp is especially suited for clamping fixtures with only little space for the installation of clamping elements. Its construction and compact design allows flexible solutions at various installation conditions. HYDROKOMP offers hydraulic rotary lever clamps which are single-acting as well double-acting. They are used in clamping fixtures whose oil supply is made through drilled channels. To swing down the clamping arm, the linear motion is used pro rata which clamps the workpiece. To unclamp, the clamping arm swings back to where the workpiece can be safely taken out.

You can order standard clamping arms from different materials and various lengths as accessories. The cylinder can also be assembled with special and self made clamping arms. The clamping force depends on the length of the clamping arm.

-

partial retractable housing

-

various installation options

-

easy loading and unloading of the fixture

-

clamping arms can be optimized on workpieces

-

inductive or pneumatic position control optionally available

-

standard cylinders and special designs available

![]()

Operating conditions:

The clamp arm is coupled with the piston rod. In single-acting cylinders the clamping arm is opened through the reset spring. In double-acting cylinders this is done through the pressure medium. When installing a rotary lever clamp, the flange face should be adapted to the height of the workpiece. With that, the clamping point should be horizontally. Despite the short clamping stroke, workpiece tolerances can be optimally compensated. The rotary lever clamp is suited for any installation positions. For the hydraulic variation we recommend hydraulic oils according to DIN 51524 (HL, HLP) as pressure medium.

Safety instruction:

Rotary lever clamps can generate great forces. Workpieces and fixtures must be suitable for this. During operation, danger of crushing is given. Accident prevention regulations must be observed. The rotary lever clamps must regularly be checked for contamination and cleaned when necessary.

The rotary lever clamp is basically suitable for any mounting position. However, it must be ensured that the chosen installation position does not enable the accumulation of metal shavings in the swing range of the clamping arm during the operation.

Application example

Multiple workholding fixture

Multiple workholding fixture with double-acting rotary lever clamps (piston Ø 12 mm) for two-sided machining, even through the fixture plate.

The workholding fixture has six clamping sets, each with six rotary lever clamps. Respectively with three elements, the clamping operation takes place sequentially controlled by a sequence valve.

The loading and unloading is done by a robot, which also positions the workpieces. This ensures the collision-free clamping operation.

Data sheet 250-10

Operating pressure:

pmax. 400 bar (hydraulically), 12 bar (pneumatically)

Operating method:

single-acting or double-acting

Design:

for hydraulic or pneumatics

Piston Ø:

12, 16, 20, 25, 32, 40 or 50 mm

Clamping force:

from 1,1 kN at 100 bar up to 95 kN at 400 bar

Oil supply:

drilled channels

![]()

Data sheet (download here) and step files on TraceParts:

Designs:

hydraulically, single-acting

with reset spring,

materials:

housing steel, burnished,

piston tempered,

scope of supply:

without clamping arm

hydraulically, double-acting

materials:

housing steel, burnished,

piston tempered,

scope of supply:

without clamping arm