Pneumatic swing clamp cylinders for magnetic sensors, upper flange, double-acting, pmax. 7 bar

Description:

Swing clamps of this design are used as pull-type cylinders. Pressure is applied to the annular surface of the piston for tensioning. During the linear movement, the piston also moves rotationally determined by the selected swing curve at a defined angle. Only after the linear and rotational movements are completed, the piston will move linearly in the clamping area. It is important that the swing movement of the mounted clamping arm is not hindered, because a overload or collision protection is not included in the design. Overload protection can be found in many Hydrokomp hydraulic swing clamps.

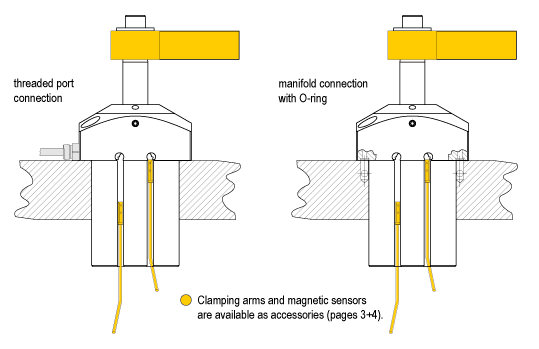

The pneumatic swing clamps are equipped with a permanent magnet on the piston. With the magnetic sensors available as accessories, positions of the piston can be measured and confirmed.

Special notes:

The magnetic sensors react to the permanent magnet inside the cylinder. Steel chips from machining or other outside influences can impact the magnetic field, therefore the switching point can change. For this reason steel materials should not come close to the cylinder. A minimum distance of 30 mm should be maintained.

Special features:

-

Monitoring of piston position

-

Low component height after installation

-

Compressed air supply through drilled channels or threaded ports

-

Fixture can be easily loaded and unloaded

-

Easy to assemble with self designed clamping arms

-

Standard and special clamping arms are available

Design:

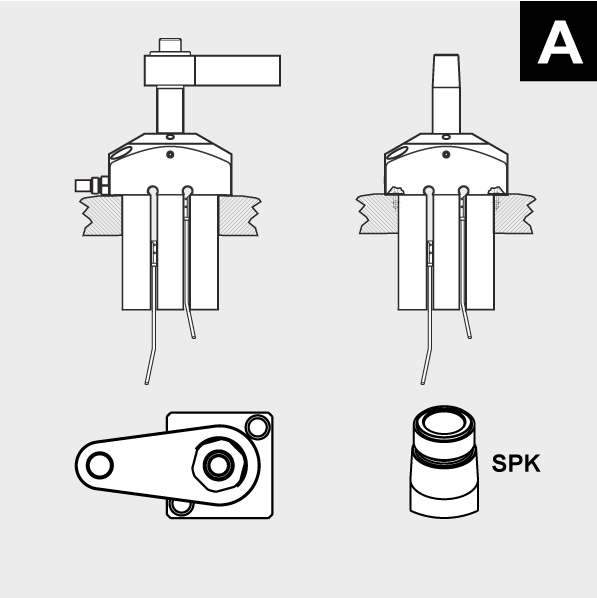

Clamping arm holder:

Taper:

Clamping arm:

- SPK

Data sheet 240-80

Operating pressure:

pmin. 3 bar - pmax. 7 bar

Swing motion:

Neutral, right turning, left turning

Operating method:

double-acting

Swing angle:

90°

Design:

A (upper flange)

Piston Ø:

20, 32, 40, 50 und 63 mm

Clamping stroke:

7, 9, 15 or 18 mm

Clamping arm holder:

taper holder

![]()

Overload protection:

without

Position control:

without

Oil supply:

pipe thread or manifold connection with O-ring

Data sheet (PDF):

Selection guide: