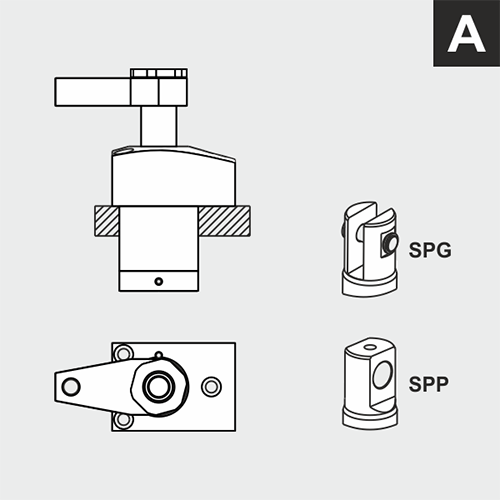

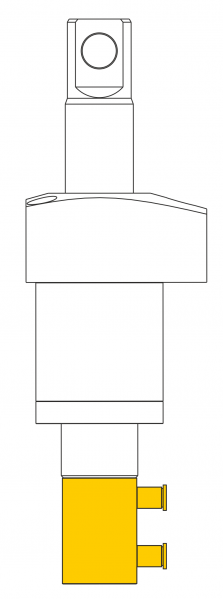

Swing clamps, with upper flange (A), position control optionally

Description

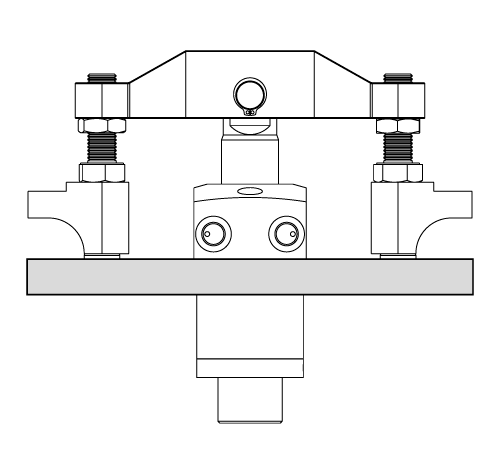

Swing clamp cylinders release the clamping point on the workpiece. With this, it is easy to change the workpiece. This hydraulic swing clamp cylinder operates as single-acting or double-acting traction cylinder, whereas part of the stroke is used to rotate the piston. The model with 0° swing angle operates only vertical as traction cylinder. You can select between right or left turning versions with various standardized swing angles.

For oil supply, the cylinders are equipped with threaded port and manifold connection with O-ring for drilled channels. To guarantee a long lifetime the cylinders have an integrated metal wiper as standard. The swing clamp cylinder can be optionally supplied with a inductive or pneumatic position control. This feature controls the clamp and unclamp position of the cylinder. The position control is not included in the scope of supply of the standard cylinder.

For any risk of exceeding the permitted volume flow a throttle check valve must be interposed into the oil supply line.

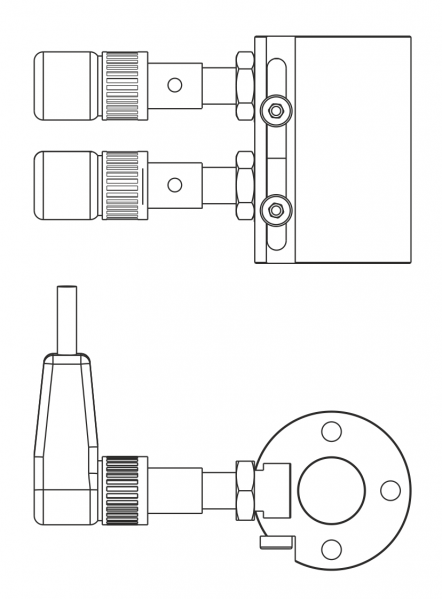

The clamping motion is initiated by a superimposed swing and stroke motion. After that, a linear clamping stroke follows. Variants with 0°, 30°, 45°, 60° and 90° swing angles are available. The permitted operating pressure is depending from the clamping arm lenght. For retaining clamping arms, the piston rod is optionally available with different holders. You can select between pendulum and clevis. The pendulum allows to retain double clamping arms. With this feature it is possible eg. to clamp two workpieces at the same time or to create a support on one side during the clamping process.

These swing clamp cylinders are equipped with a reinforced swing mechanism. Thereby an overload protection is unnecessary. The reinforced swing mechanism compensates, for example the higher loads if double clamping arms should be used.

When using self designed double clamping arms it is recommended to insert a carrier with spring elements to guarantee the neutral position. During the mounting of the clamping arm, make sure that torques are transferred in the piston rod. Hold against the clamping arm when you tighten or loosen the fixing screw.

-

protecting metal wiper

-

reinforced swing mechnism

-

inductive or pneumatic position control available

-

easy loading and unloading of the fixture

-

customer specific clamping arms can be mounted

-

standard and special clamping arms available

Design:

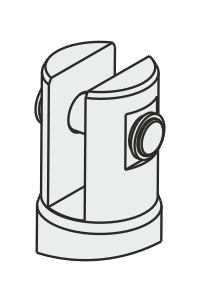

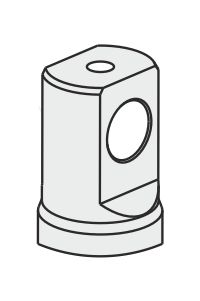

Clamping arm holders:

Application examples

Data sheet 240-20

Operating pressure:

pmax. 500 bar

Operating method:

double-acting

Swing angle:

0°, 30°, 45°, 60° and 90°

Design:

A (upper flange)

Piston Ø:

25 and 40 mm

Clamping stroke:

25 and 22 mm

Clamping arm holder:

clevis and pendulum

![]()

Overload protection:

reinforced swing mechanism

Position control:

without, pneumatic, inductive or shift rod

Oil supply:

pipe thread or manifold connection with O-ring

Data sheet (PDF):

Position control:

![]()