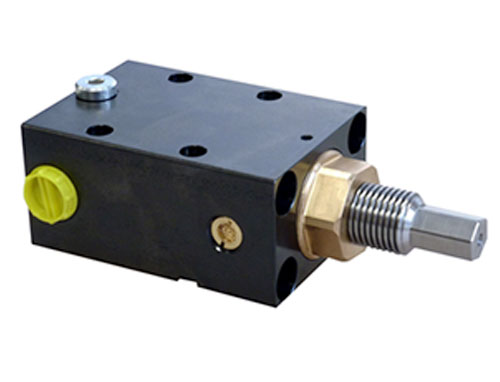

Screw pumps with block housing or threaded body housing

Where small clamping systems without oil supply are to be implemented, a screw pump can be integrated for pressure generation. There are two housing variations available. The screw pump with block housing and G1/4 threaded port or manifold connection and the screw pump with threaded housing.

Screwing in the spindle compresses the fluid medium. The pressure within the clamping system increases. Once the operating pressure is reached, the clamping process is implemented and the workpiece is clamped. Unscrewing the spindle decreases the pressure. The clamping system de-clamps and releases the workpiece again.

-

ideal for small clamping systems without external oil supply

-

actuation of the spindle with tools possible

-

compact design

-

standard pumps and special designs available

Important information:

For filling the screw pump with hydraulic oil, the spindle should be screwed in. Then, fill in the oil through the fill port and in doing so, unscrew the spindle again. The clamping system may not contain air bubbles as these might cause pressure drop. After the filling process, the clamping system needs to be completely vented. For that, an vent screw has to be positioned at the highest point.

Screw pumps and clamping elements form a closed system. All connected components must be leak-proof in passive state. The stroke volume of the screw pump may only be to 60-70% of full capacity. This means, you should not screw the spindle up to the edge.

The clamping force can be monitored with an optional pressure gauge. To operate the spindle, also tools with torque control can be implemented. It is not recommended to use impact wrenches for that.