Pull-type cylinders

Description

This single-acting pull cylinder is suitable for smaller plants which are tact-independent. The built-in reset spring only serves for bringing the piston into the retracted position. The reset time depends on several conditions. So, an exact reset time can not be calculated. If feed and reset are to act tact-dependent and/or force loaded in a set interval, we recommend to use our double-acting block-cylinders. The pull cylinder is available in various designs with threaded port or manifold connection with O-rings.

When mounting the pull cylinder, for example through the cross holes, it is important to have the cylinder to the front form-closed supported starting with an operating pressure of 250 bar and up, in so far as the mounting is made transverse to the force direction.

The user also has to prevent foreign particles and liquids from ingress into the spring chamber of the pull cylinder by a cover or preventive cylinder arrangement. If desired, a vent line can be additionally connected at the threaded port or manifold connection.

-

ideal for non-tacted machine plants

-

space-saving installation

-

4 mounting options

-

metal wiper as standard

-

vent line connectable

-

standard cylinders and special design available

Data sheet 200-6

Operating pressure:

pmax. 500 bar

Operating method:

single-acting with reset spring

Piston Ø:

16, 20, 25, 32, 40, 50, 63, 80 and 100 mm

Stroke:

8, 10 and 12 mm

Traction force:

from 40 N up to 1200 N

Thrust force:

from 1,1 kN at 100 bar up to 235 kN at 500 bar

Oil supply:

threaded port G1/4 or G1/2 or manifold with O-ring![]()

Sealing:

NBR -10°C up to +80°C, FKM up to 150°C

Wiper:

soft wiper and metal wiper

![]()

Data sheet (PDF):

Designs:

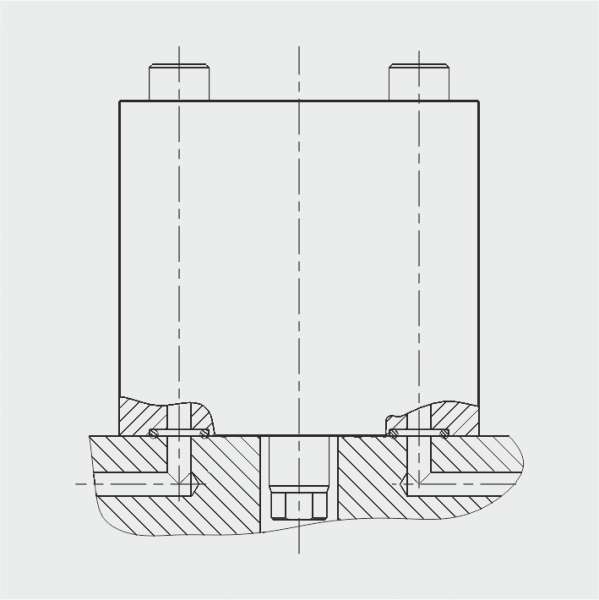

Type A

threaded body G1/4 or G1/2

Mounting bores

in the housing

lengthwise and crosswise

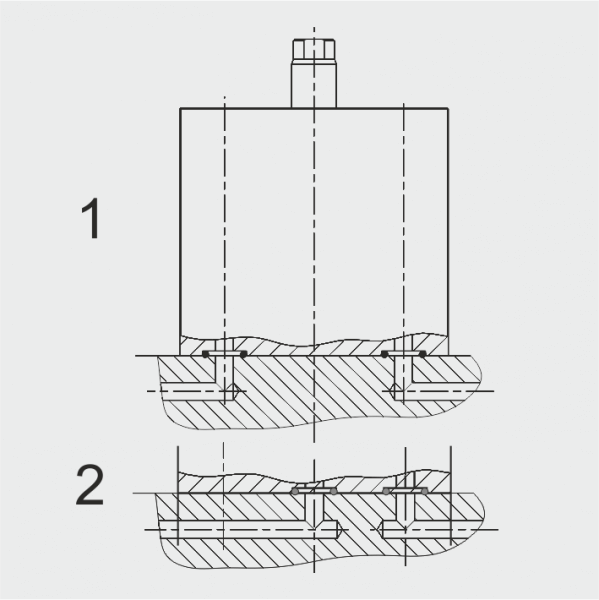

Type D

manifold with O-ring,

bottom side

Mounting bores

in the housing lengthwise

fig. 1 variant „standard“

fig. 2 variant „centered bore“

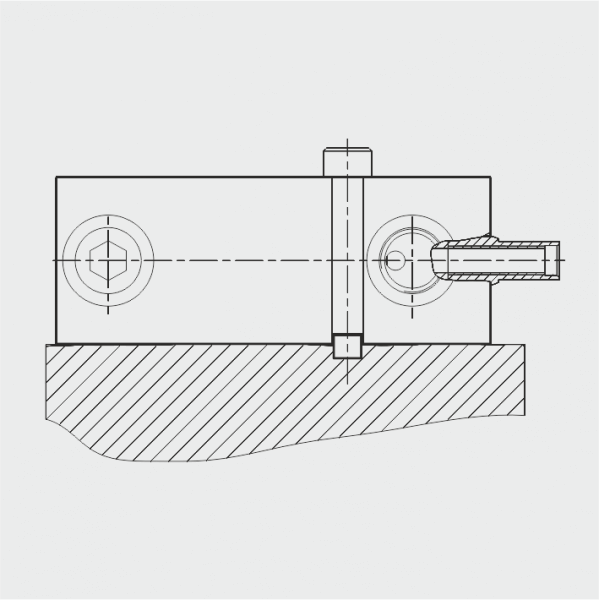

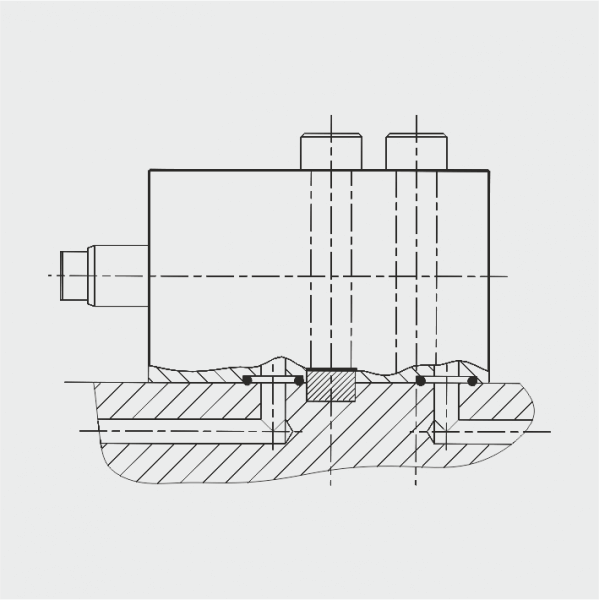

Type E

manifold with O-ring, broadside

Mounting bores

in the housing, crosswise