Threaded body cylinders, with reset spring

Description

These threaded body cylinders are used as space-saving clamping cylinders and are notable for their compact design. By the internal stroke limiters, the cylinder can also be operated even without a counter clamp surface. The use of the double wiper ring reduces dynamic leakage.

The threaded body cylinder is hydraulically operated, single-acting. Return is by means of a build-in spring. The hydraulic oil is fed through drilled holes. The cylinder is sealed against the base of the screw-in hole by means of a ring seal. As a result of the plunger design, bleeding of the piston rod space is unnecessary.

-

diversity due different designs

-

also retracted fully loadable

-

ventilation connection unnecessary

-

with spherical piston surface

-

without or with double wiper available

-

standard cylinders and special designs available

Important instruction:

The cylinder can be loaded up to the maximum clamping force in the retracted position. Protect the cylinders against the direct influences of aggressive abrasives and coolants. For general operating conditions and other information, read the document Recommendations & Specifications.

![]()

Application example

Multiple clamping fixture for series manufacture

Used in a multiple clamping fixture for series manufacture of different workpieces (eg. flange plates).

The fixture is located on a rotary table. The clamping length is 600 mm.

48 single-acting threaded body cylinders with a piston diameter of 20 mm and a stroke of 15 mm are used, and a rotary valve coupling, single-acting with 6 stations with a nominal diameter of 5.

Data sheet 210-2

Operating pressure:

pmax. 400 bar

Operating method:

single-acting with reset spring

Piston Ø:

12, 16, 20, 25 and 32 mm

Stroke:

10, 12, 15, 16 and 20 mm

Thrust force:

from 1,1 kN at 100 bar up to 32 kN at 400 bar

Traction force:

from 30 N up to 200 N

Oil supply:

drilled channels

Sealing:

NBR -10°C up to +80°C, FKM up to 150°

Wiper:

without or with double wiper

Data sheet (PDF):

Designs:

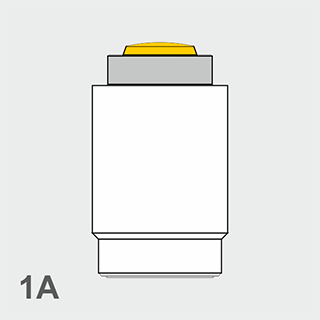

Type 1A

with reset spring,

without double wiper,

without screw-on edge,

piston with spherical surface

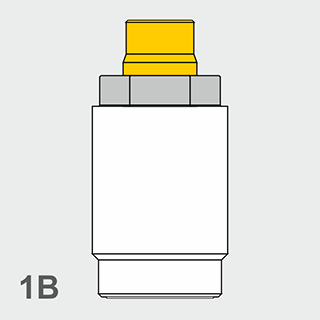

Type 1B

with reset spring,

without double wiper,

without screw-on edge,

piston with internal thread

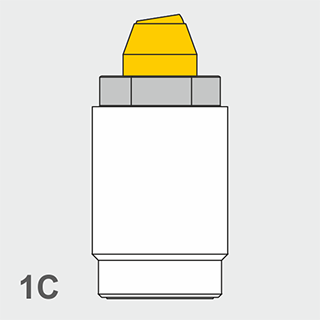

Type 1C

with reset spring,

without double wiper,

without screw-on edge,

piston with pendulum support

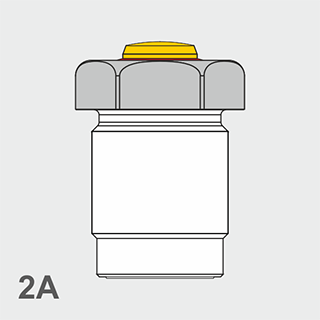

Type 2A

with reset spring,

with double wiper,

with screw-on edge,

piston with spherical surface

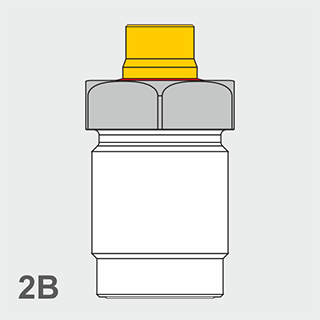

Type 2B

with reset spring,

with double wiper,

with screw-on edge,

piston with internal thread

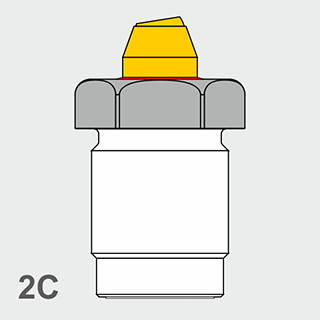

Type 2C

with reset spring,

with double wiper,

with screw-on edge,

piston with pendulum support