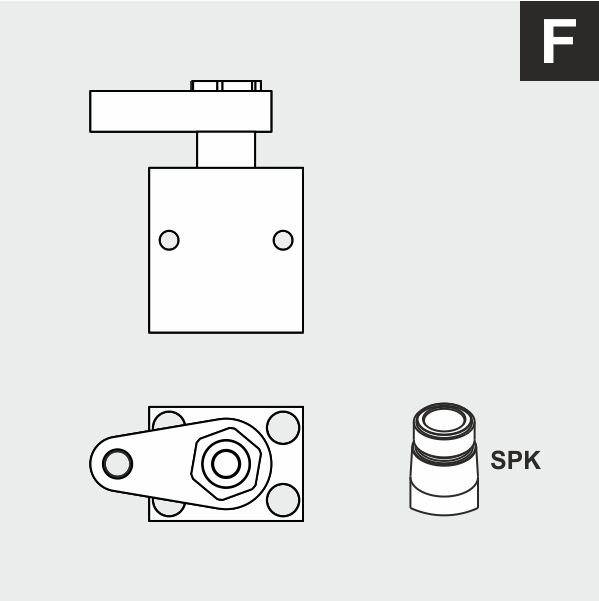

Swing clamps, with block housing (F)

Description

Swing clamp cylinders release the clamping point on the workpiece. With this, it is easy to change the workpiece. This hydraulic swing clamp cylinder operates as double-acting traction cylinder, whereas part of the stroke is used to rotate the piston. The model with 0° swing angle operates only vertical as traction cylinder. To guarantee a long lifetime the cylinders have an integrated metal wiper as standard.

For hydraulic oil supply, the cylinders are equipped with threaded port and manifold connection with O-ring for drilled channels. You can select between right or left turning models with various standardized swing angles. The integrated overload protection protects the swing mechanism from demage due blockage of the rotation or improper assembly of the clamping arm.

For any risk of exceeding the permitted volume flow a throttle check valve must be interposed into the oil supply line. Counter-hold the clamping arm when tightening or loosening the counter nut in order to prevent torque transfer to the piston rod and to avoid damage to the ball guide.

Models with 0°, 30°, 45°, 60° and 90° swing angles are available. The permitted operating pressure is depending from the clamping arm length. Models with other swing angles can be supplied as special designs. Except from standard clamping arms also special clamping arms can be assembled. The maximum operating pressure of 500 bar does not apply for each clamping arm length. For details about the permitted operating pressure see the diagrams on the data sheet.

-

protecting metal wiper

-

integraded overload protection

-

oil supply via drilled channels or threaded ports

-

easy loading and unloading of the fixture

-

customer specific clamping arms can be mounted

-

standard and special clamping arms available

Design:

Clamping arm holder:

Data sheet 240-40

Operating pressure:

pmax. 500 bar

Operating method:

double-acting

Swing angle:

0°, 30°, 45°, 60° and 90°

Design:

F (block housing)

Piston Ø:

25, 40 and 63 mm

Clamping stroke:

7, 8, or 11 mm

Clamping arm holder:

taper, ratio 1:10

![]()

Overload protection:

with

Position control:

without

Oil supply:

pipe thread or manifold connection with O-ring

Data sheet (PDF):

Selection guide: